- +86 19149417743

- Zhengzhou, Henan Province, China

- Mon-fri: 8am - 7pm

Get a quote

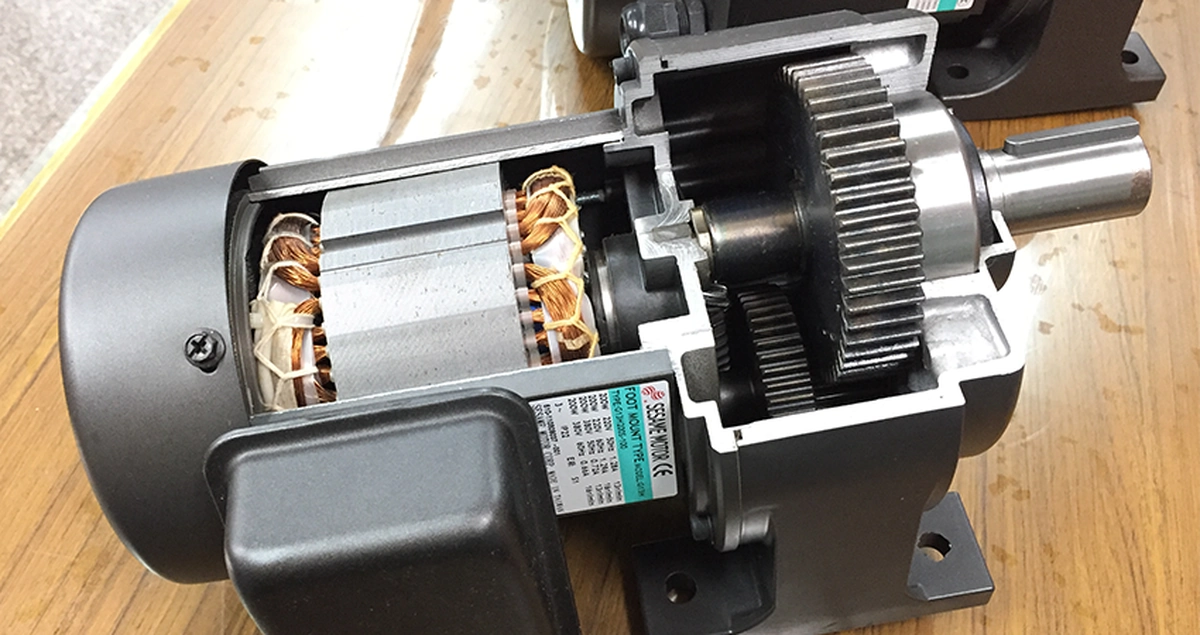

The factors to consider when choosing a gearbox are as follows:

One of the key factors in choosing the right gearbox is considering the load requirements, including torque, speed, and duty cycle. If your application requires high torque and low speed, then selecting a gearbox with strong torque transmission capability is necessary. Additionally, the duty cycle is also a factor to consider, especially in applications that require frequent starting and stopping.

Choosing an efficient gearbox can reduce energy losses and improve the overall efficiency and performance of the system. The quality of the gears is also very important, as high-quality gears have higher manufacturing precision, can reduce wear, and extend the lifespan. For example, for high-load applications, selecting heat-treated high-strength gears can enhance the reliability of the entire system.

Proper lubrication and regular maintenance are crucial for the performance and longevity of the gearbox. Choosing the right lubricant and following the manufacturer's maintenance recommendations can ensure the gearbox operates smoothly. For some applications in high-temperature environments, high-temperature lubricants may be required to ensure the reliability of the gearboxes under extreme conditions.

When choosing a gearbox, it is necessary to consider the available space and weight restrictions. If your equipment has limited space, you may need to choose a compact gearbox to better integrate it into the limited space. In addition, weight restrictions are also a factor to consider for mobile devices or vehicle applications.

In addition to the initial purchase cost, the long-term cost-effectiveness of the gearbox should also be considered. Some high-efficiency gearboxes can reduce energy consumption, thus saving energy costs in the long run. In addition to operating costs, maintenance costs and the availability of spare parts are also cost factors that need to be considered.

When choosing a gearbox, it is necessary to consider its compatibility with other components and systems. If the gearbox needs to work in conjunction with a motor or other transmission devices, it is important to first ensure their axial alignment and dimensions for better compatibility with other components. In addition, compatibility with the control system is also a factor to consider.

Choosing a reliable gearbox manufacturer that provides good service support is very important. It is best to choose a manufacturer with a good reputation and the ability to provide timely technical support so that even if you encounter any problems during use, you can get technical support on time to ensure that the issues are properly resolved. Lunyee has a comprehensive after-sales system and an experienced technical team, available 24 hours online without interruption, to ensure that your problems can be resolved promptly.

2024-08-30 16:01:40

Engineering

2024-08-30 16:01:40

Engineering

2024-07-26 14:09:13

Engineering

2024-07-26 14:09:13

Engineering

2024-07-18 09:42:00

Engineering

2024-07-18 09:42:00

Engineering