- +86 19149417743

- Zhengzhou, Henan Province, China

- Mon-fri: 8am - 7pm

Get a quote

Gearboxes play a vital role in transferring power from the engine to the wheels in a synchronized, efficient manner. A closer look inside reveals intricately engineered components working together.

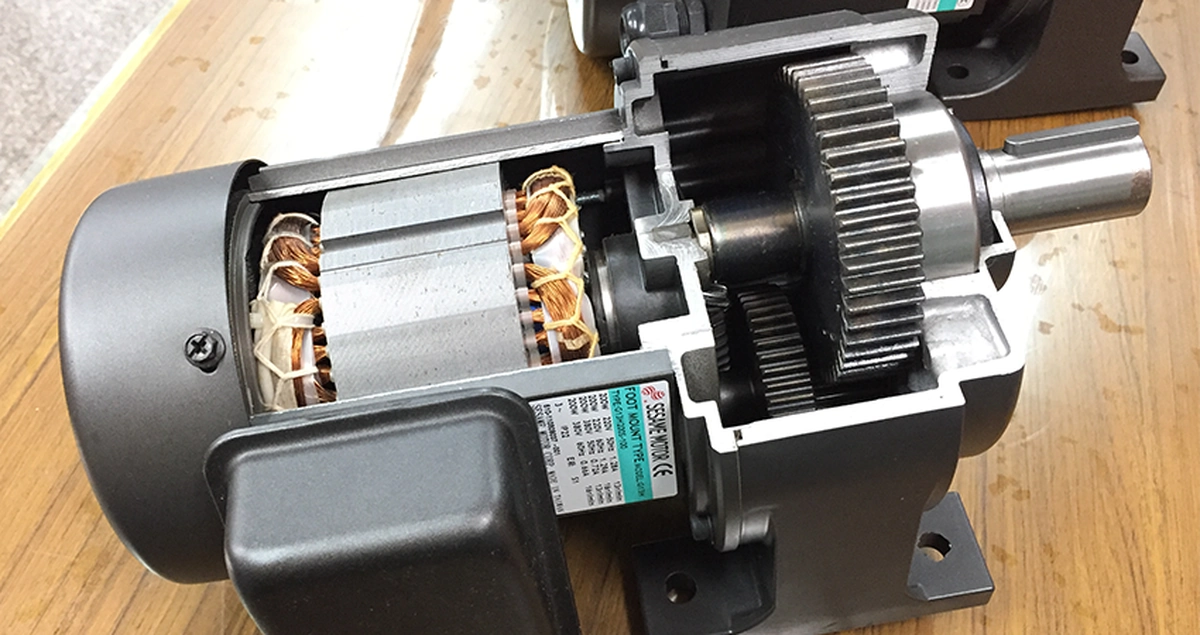

The main components include the transmission, transfer case, and final drive. The transmission houses 5-8 gears stacked vertically on either side of the transmission case. Forward gears are located on one side while reverse gears are on the opposing side. Hardened steel shafts with precision-fitted bearings connect each gear to transmit torque from the input shaft to the output shaft.

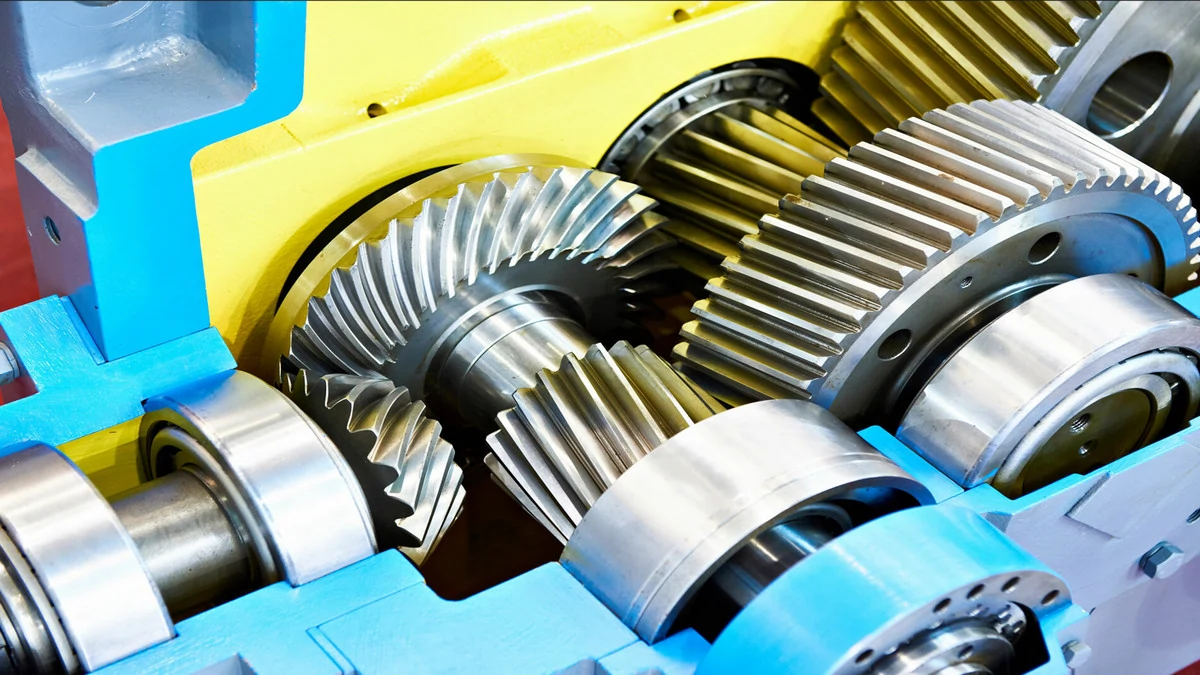

Gearboxes utilize various gear types including helical gears, which are cut at an angle to reduce noise. Planetary gears form the basis for automatic transmissions, arranged in networks of sun, ring, and planet gears that rotate and revolve around each other. Spiral bevel gears featuring intersecting conical surfaces are commonly used to change the direction of rotation between the transmission and transfer case by 90 degrees.

Manual transmissions use syncros to engage gears smoothly. A gear lever is connected via cables to move sliding gear sleeves. Automatic transmissions contain hydraulic pistons controlled by solenoids that engage multiple clutch packs to select optimal gear ratios based on sensors reading road speed and throttle position.

An electric oil pump continually circulates synthetic automatic transmission fluid through precision-machined internal slots and galleries. This both lubricates and cools the mainshaft, layshaft, and other high-wear components including gears and bearings. The fully-enclosed, seal transmission casing protects these internal components submerged in fluid.

In summary, coordinating diverse gear and shaft arrangements transmits engine power effectively through ingenious mechanical interaction. Precise production and assembly are needed for long-term reliability.

2024-03-06 17:12:12

Engineering

2024-03-06 17:12:12

Engineering

2024-02-29 15:08:43

Engineering

2024-02-29 15:08:43

Engineering

2024-02-27 10:12:57

Engineering

2024-02-27 10:12:57

Engineering