- +86 19149417743

- Zhengzhou, Henan Province, China

- Mon-fri: 8am - 7pm

Get a quote

Gearboxes play a vital role in various mechanical systems, enabling the efficient transfer of power and torque between different components. This essay aims to provide a detailed understanding of what a gearbox does and its significance in mechanical engineering. By exploring the basic principles, types of gearboxes, and real-world applications, readers will gain valuable insights into the functionality and importance of this essential mechanical component.

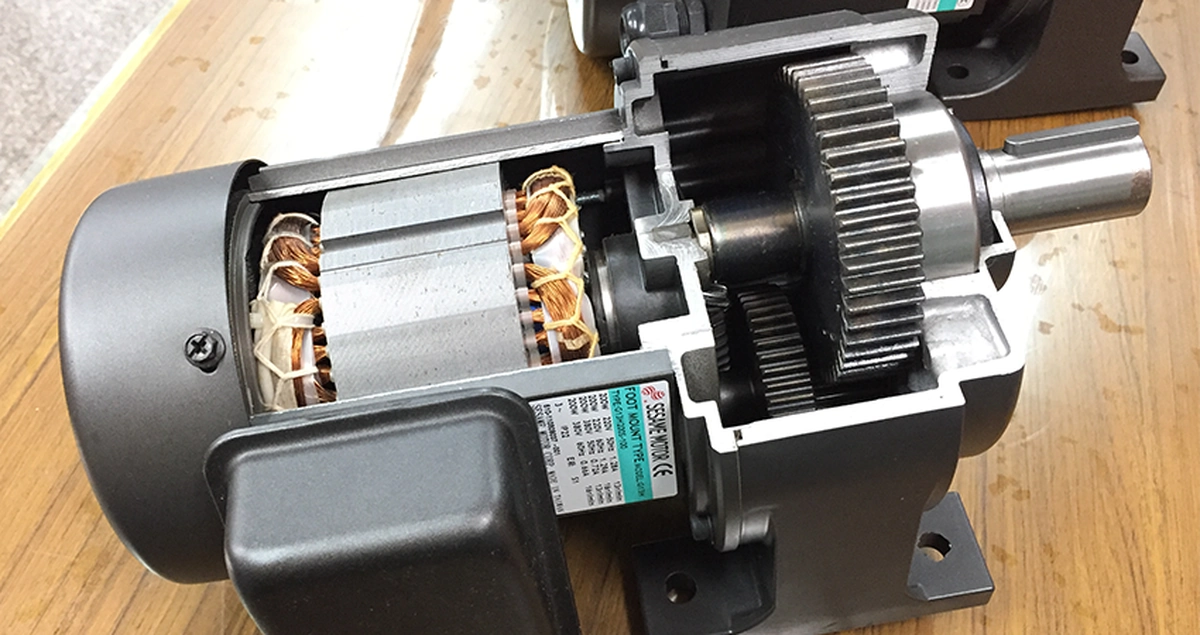

Gearboxes are mechanical devices designed to transmit and modify rotational motion and torque between different components within a system. They consist of a set of gears with varying sizes and configurations, working together to achieve specific speed and torque requirements. This section will delve into the fundamental purpose of gearboxes, emphasizing their role in power transmission, speed reduction or increase, and torque amplification or reduction.

There are several types of gearboxes, each serving specific purposes based on the requirements of the system. This section will explore some of the most common types, including:

Spur gearboxes are the simplest and most common type, featuring parallel shafts and teeth that are straight and extend radially from the gear's center. They are widely used in applications where efficiency and simplicity are essential, such as conveyor systems and small appliances.

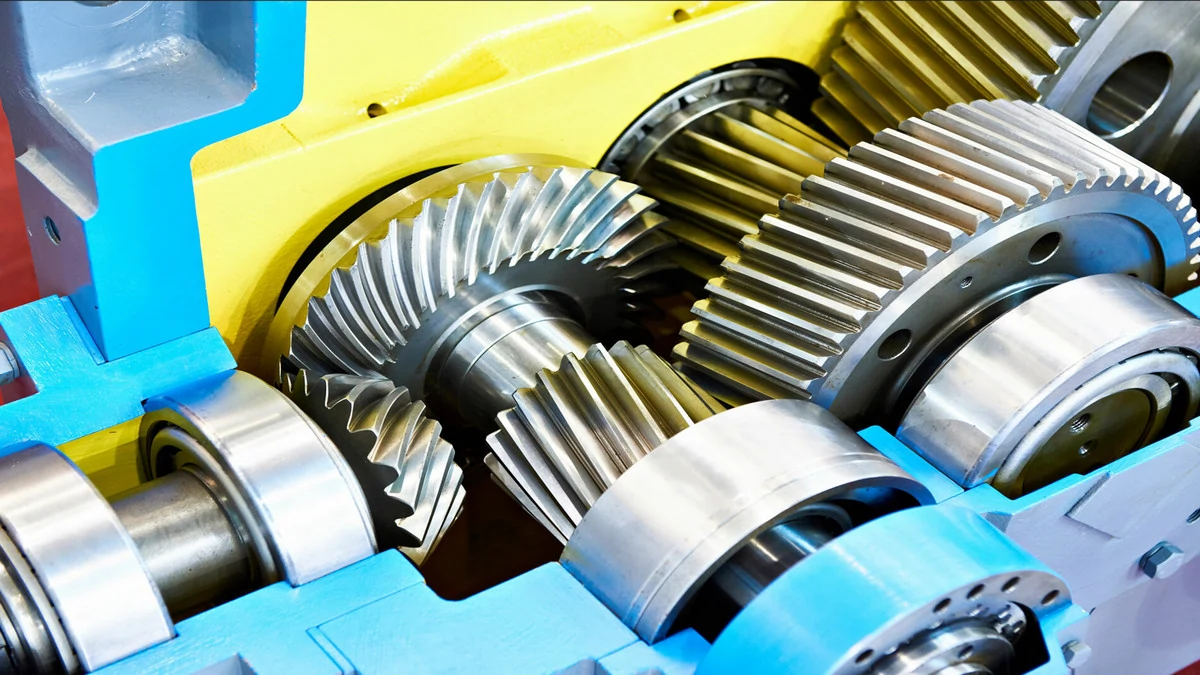

Helical gearboxes utilize helical gears, which have angled teeth that gradually engage, resulting in smoother and quieter operation compared to spur gears. This type of gearbox is often found in industrial machinery, automotive transmissions, and power generation systems.

Bevel gearboxes are designed to transmit power and torque between intersecting shafts at different angles. They are commonly used in applications where the input and output shafts need to change direction, such as in rear-wheel drive vehicles and printing presses.

Worm gearboxes consist of a worm (a screw-like gear) and a worm wheel (a gear with angled teeth). They provide high torque multiplication and are frequently used in applications requiring high reduction ratios, such as conveyor systems, elevators, and heavy machinery.

Gearboxes find extensive use in a wide range of industries and applications. This section will highlight some practical examples to illustrate the importance and versatility of gearboxes:

Gearboxes are integral components of automotive transmissions, allowing for smooth shifting between different gears and enabling the engine to operate efficiently across a range of speeds.

Gearboxes are widely employed in industrial machinery, such as manufacturing equipment, conveyor systems, and machine tools. They facilitate the precise control of speed and torque, ensuring optimal performance and productivity.

Gearboxes play a crucial role in renewable energy systems, such as wind turbines and solar tracking systems. They enable the conversion of low-speed rotational motion into higher-speed motion, maximizing energy generation efficiency.

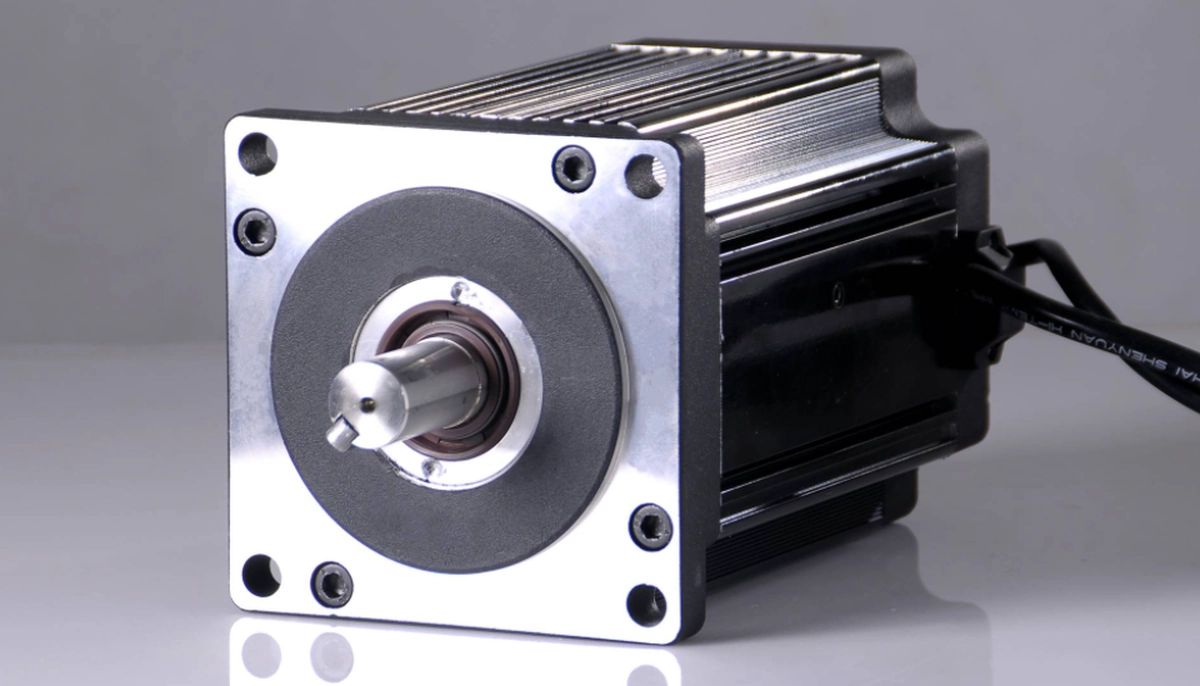

Gearboxes are essential in robotic systems, enabling precise and controlled movement of robot joints and end-effectors. They contribute to the accuracy and repeatability of robotic operations.

Gearboxes serve as critical components in various mechanical systems, facilitating the efficient transfer of power, torque, and motion. This essay has provided a comprehensive explanation of the function and significance of gearboxes, exploring their fundamental principles, different types, and real-world applications. By understanding the role of gearboxes, engineers and professionals can make informed decisions in selecting appropriate gearbox configurations for specific applications, ensuring optimal performance and reliability. With their ability to modify speed, torque, and direction, gearboxes continue to be indispensable in numerous industries, driving innovation and advancement in mechanical engineering.

2024-03-06 17:12:12

Engineering

2024-03-06 17:12:12

Engineering

2024-02-29 15:08:43

Engineering

2024-02-29 15:08:43

Engineering

2024-02-27 10:12:57

Engineering

2024-02-27 10:12:57

Engineering